Description

The extrusion process is present in all aspects of our food, handling from baby food, through breakfast cereals, followed by textured, coextruded, expanded, pet food, fish, chemical industry, among others.

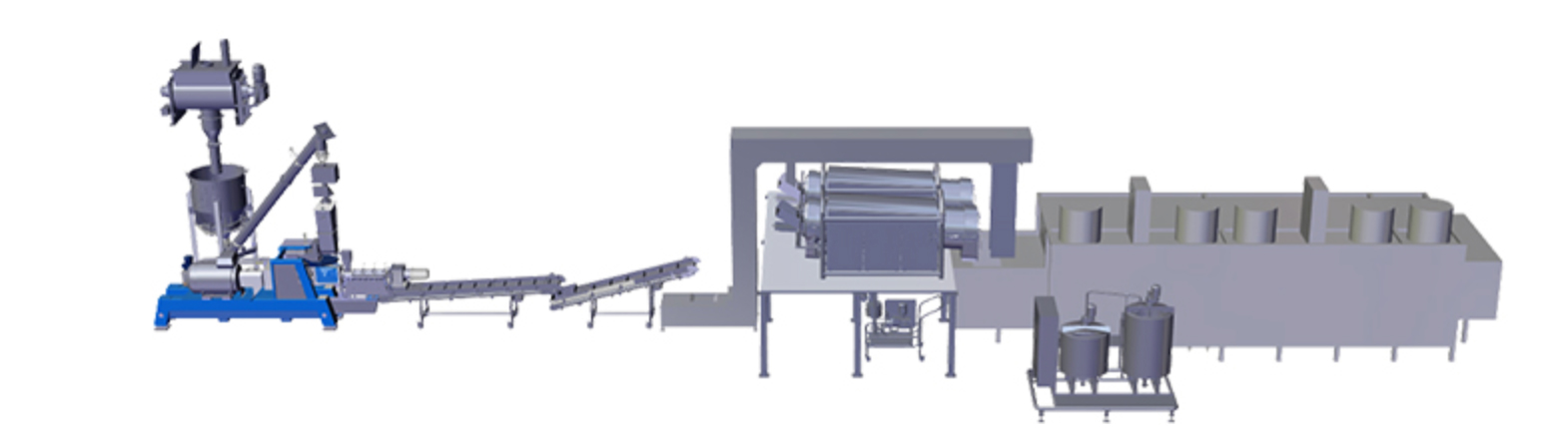

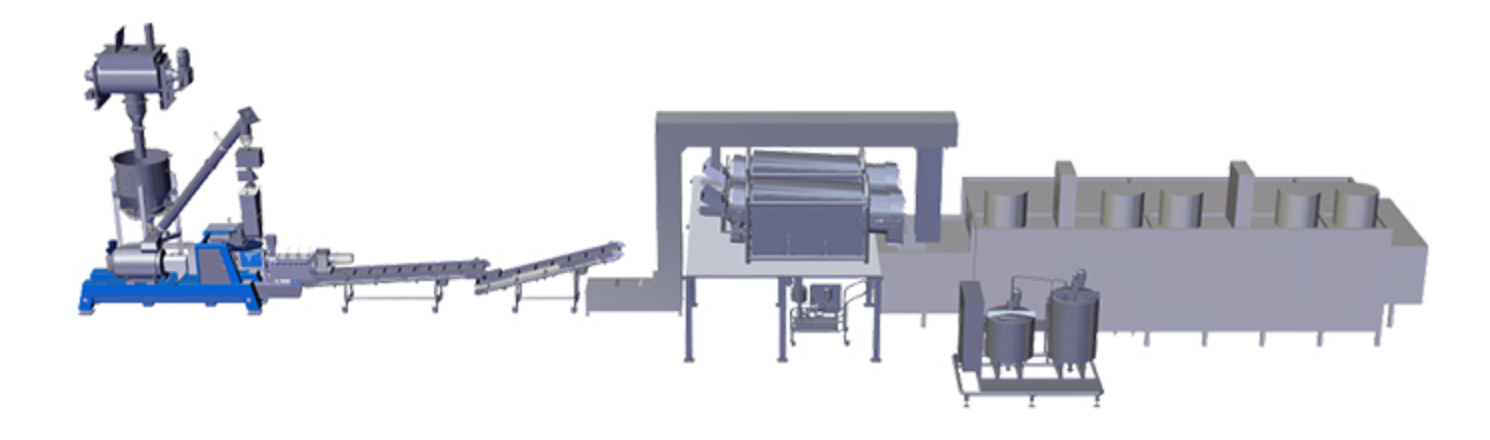

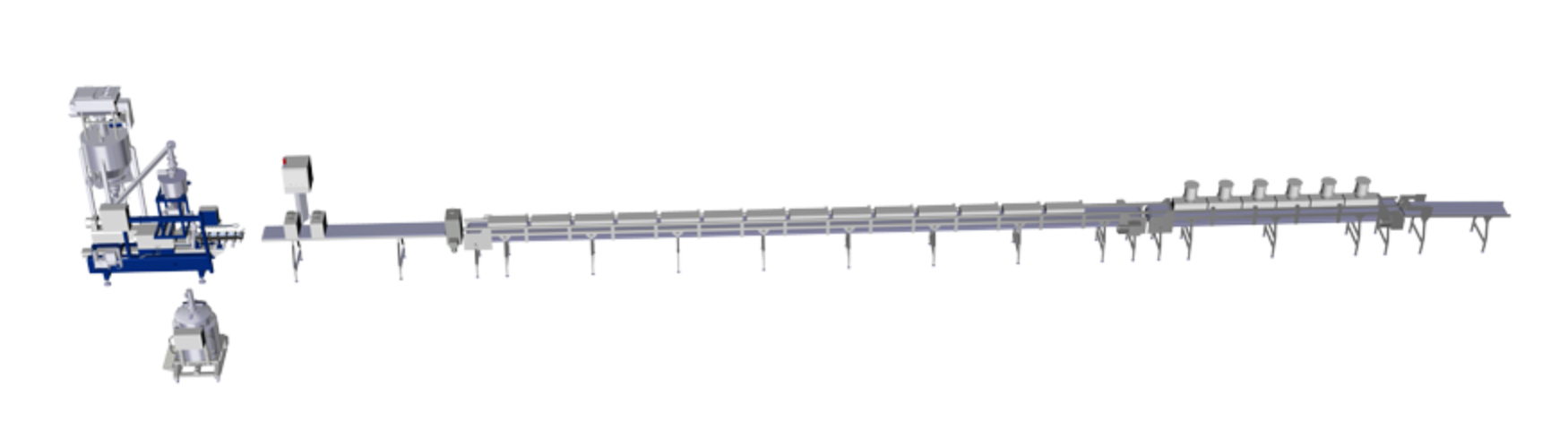

LINE OF EXPANDABLES AND CORN FLAKES FOR BREAKFAST

The cereals directly expanded They are products that have a crunchy and crunchy texture. The lines with twin screw extrusion It is and taking into account the specifications of our customers, in order to be able to produce an infinite variety of directly expanded cereals.

- Morning cereals , snacks, ingredients, stuffed products.

- Ingredients, baby food.

- Fiber Protein long.

- Couscous, small masses.

- Food for Dogs and cats , snacks, food for fish in cultivation.

AN UNLIMITED VARIETY OF SHAPES, FLAVORS AND TEXTURES

Countless ways: rings, balls, stars, petals, animals, letters of the alphabet …

- Specific covers: glaze, syrup, honey, various flavors …

- Multiple colors.

- Different scents: fruits, vanilla, cinnamon, chocolate, malt, caramel …

- Integration of different ingredients: complex and simple sugars, powdered milk, honey, cocoa, aromas, salts …

- Visible inclusions: crispy rice, different presentations, oats and wheat flakes, dehydrated fruit or vegetable particles …

- Transformation into cereal bars: puffed rice, wheat flour balls and various types of cereals

Different presentations:

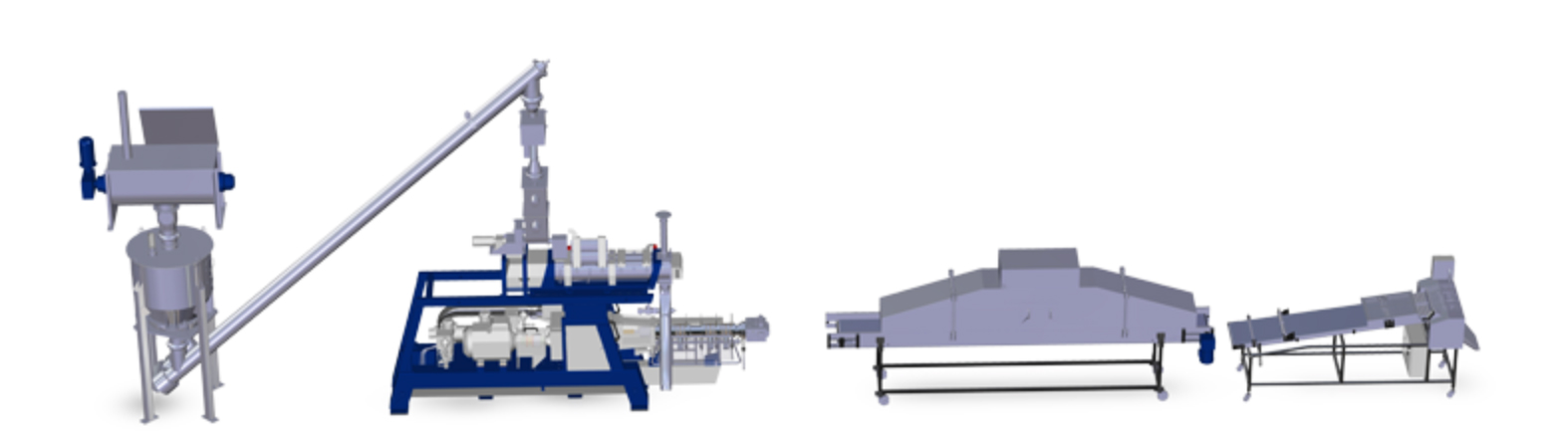

MULTI-GRAIN CHIPS PRODUCTION LINE

HOW DOES A MULTI-GRAIN CHIPS PRODUCTION LINE WORK?

The ingredients are weighed and mixed before proceeding to the process of extrusion, and then go directly to the matrix of twin screw extrusion . Twin screw extruders cook and process ingredients using a combination of thermal energy, mechanical cutting, and moisture incorporation. Temperature control is essential in the production process of multigrain chips because the level of cooking will determine the quality characteristics of the final product. A blade at the end of the twin screw extruder is responsible for making individual cuts and transported to a device where post-cooking operations will be carried out. Fried or baked extruded chips are seasoned with different flavors, such as onion, cheese, barbecue, pepper, chili, curry, etc. flavors. Generally, the process of seasoned takes place in a rotary drum where dry seasonings are incorporated in proportions ranging between 1% and 10%, depending on the characteristics desired for the product.

BREAD SNACKS PRODUCTION LINE

HOW DOES A BREAD SNACK PRODUCTION LINE WORK?

Once the ingredients of the formula have been dosed and weighed, they are mixed and brought to the extruder, and it is fired using the appropriate thermo-mechanical levels. Once extruded, the cooked dough is cut into 45 ° or 90 ° slices. An innovative and flexible cutting system is used, which was developed and is ideal for slicing bread sandwiches extruded that will later be seasoned. The incorporation of flavors through seasoning is carried out in several phases within the same extruder, thus avoiding oil-based coatings and reducing the fat content of the products. They are transported to a dryer band, in which the ideal temperature and humidity to reach the programmed humidity and browning level.

|  |  |

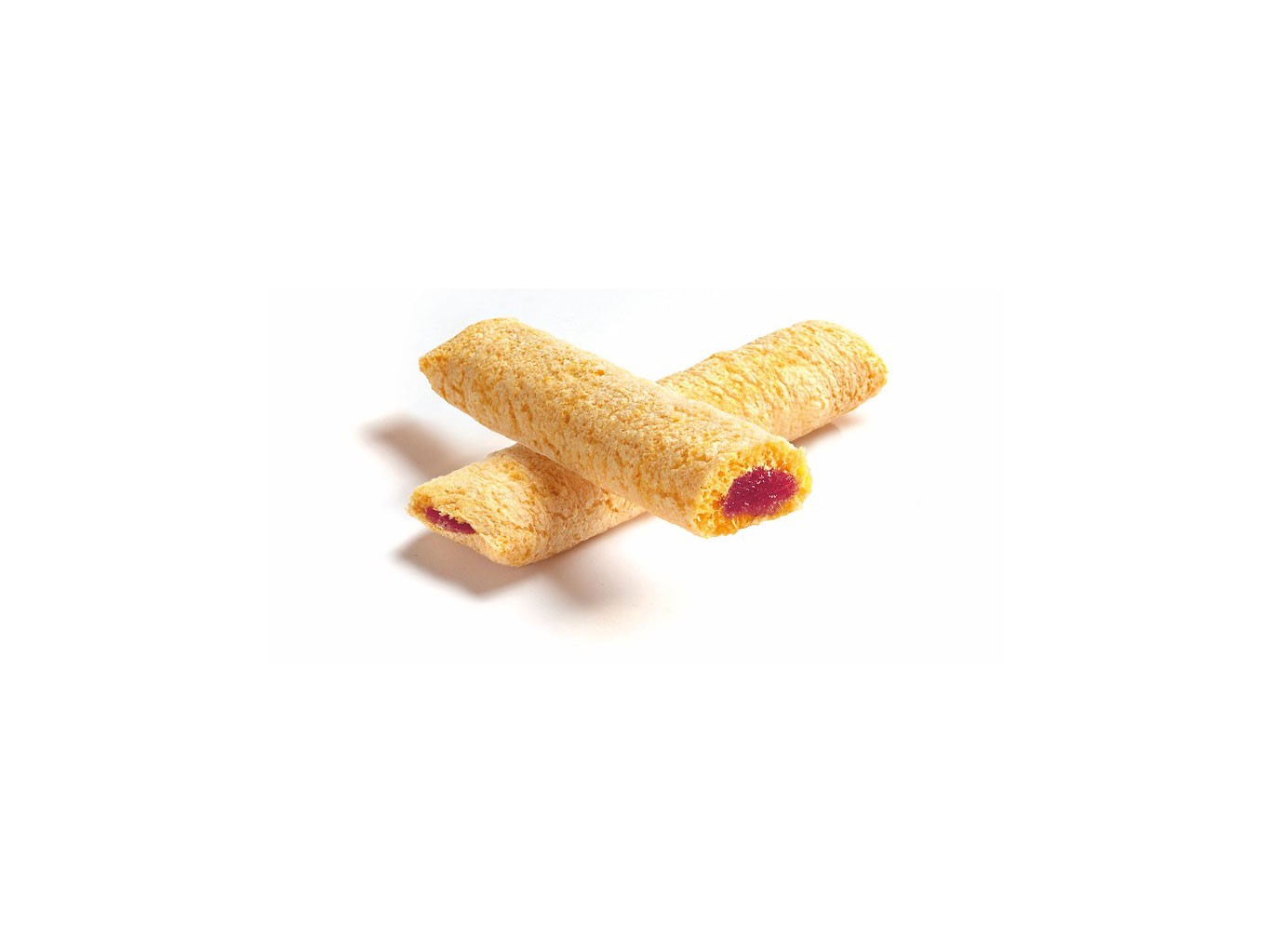

COEXTRUDED PREPARATION LINE – FULL FLAVORED CEREALS

The sugary and filled products ready to be consumed for breakfast are made up of cereals directly expanded Y coextruded by means of bars containing cream, syrup and different kinds of sweet pastries. They are particularly innovative and easily adaptable to meet the changing demands of the consumers . We have the technology to develop all kinds of products with these characteristics, providing a great variety of external parts and fillings that are really tasty and nutritious.

COEXTRUDED BARS

|  |

CRISPY FLAT CORDUROY PRODUCTION LINE

HOW DOES A CRISPY BREAD PRODUCTION LINE WORK?

A mixture of i ingredients and are introduced to the extruder, this being the place where the liquid additives are injected through the t ambor . The mass passes through the barrel, where a threaded assembly and mechanical and thermal energies cook the pasta simultaneously. The texturing process occurs when the dough is cooked (extruded) in the barrel of the extruder, outside the mold. Product batches are rolled, sliced, roasted and packed .

Processing line stuffed products It is similar to the crisp bread production line, but uses a system of coextrusion . Stuffed bread can be made using the same machinery that was used to make crusty flatbread, adding a kit of coextrusion .

PASTA PRODUCTION LINE

QUALITY FROM BEGINNING TO END

If we talk about short pasta, AVANN TECH. to developed systems processing machines, which are capable of producing the main short pasta formats: macaroni , penne , elbows, vermicelli, farfalle , angel hair, egg noodles, etc. Short pasta production systems are designed to meet the highest standards of hygiene, flexibility, consistency, productivity and maintenance. AVANN TECH systems. they maintain high quality standards throughout the production process: perfect dosage of ingredients, homogeneous mixing, molding and cutting to size, pre-drying by rotating rotary drying, and optimal cooling, storage and packaging processes.

For the drying phase, our systems offer a particular advantage since they use an exclusive VHT (Very High Temperature) drying system, which provides great advantages, including: reduced processing time, improvement of the quality of the final product (especially for pasta made with soft flour), minimal product waste, fast conversion times and hygienic processing.

SHRIMP FOOD PRODUCTION LINE

HOW IS FISH FOOD MADE?

Ingredients are selected and ground from high quality (fish meal, cereals, vegetable proteins …) taking into account specific nutritional requirements and the ideal size for to satisfy the needs of fish or shrimp.

The distribution of size of the particles is a key factor to produce premium quality granules, which is why the phase of grinding it is crucial in the brewing process. After grinding, the powder is mixed with ingredients such as vitamins, mineral premixes … before proceeding to the preparation phase. conditioning.

He then goes on to the cooking for extrusion , being the same the most important phase of the process, and which is carried out in three stages: pre-conditioning, cooking by extrusion and texturing / molding. The extrusion firing with a twin screw system allows a perfect mixture to be carried out and to apply cutting control parameters, temperature and residence time until reaching the most High standards physical and nutritional. By means of direct steam injection by means of a ventilation device and a efficient keg cooling adjustable screw speed, screw configuration, shear and temperature is it so perfectly controlled; which results pellets with functional and nutritional properties optimized , such as: apparent density, calibration, degree of cooking, better ratio between proteins and lipids, etc.

Later, the pellets can be oil coated and cooled, in order to complete the process.