Description

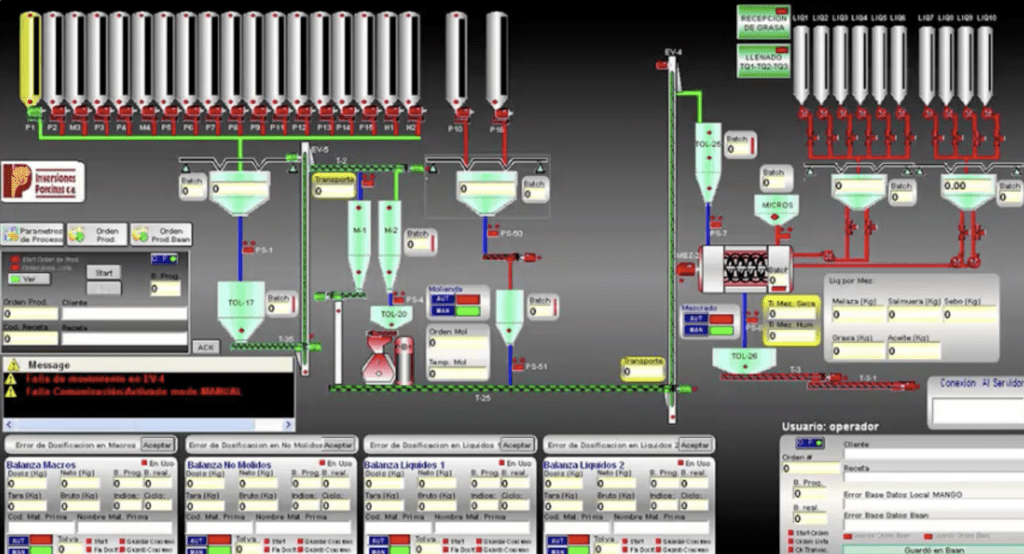

A well-balanced food, without errors in the development of the formulation, with a precise dosage, weighing and mixing, means taking into account the control of each specific process.

As a result we will have a product with high standards in manufacturing that ensure the reliability of customers.

Advantages:

- Processes automatic without intervention hand in hand with the operators.

- Monitoring of the traceability of the ingredients used in each formula.

- Decrease in risk due to cross contamination.

- Tracking at all times of each batch of feed to be produced.

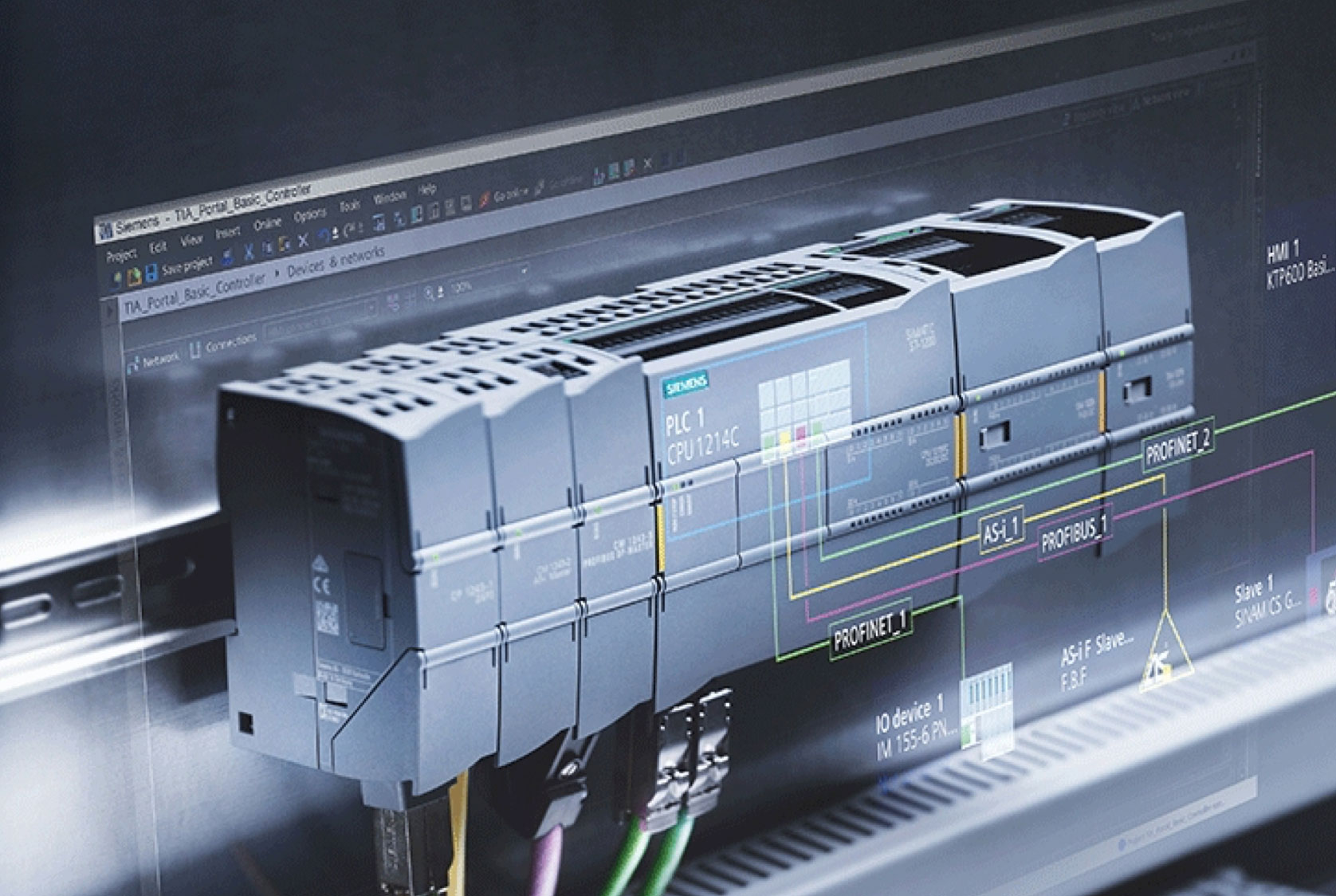

- Automation of raw material storage, milling, mixing, pelletizing, extrusion, drying, finished product, liquid application, bagging processes.

- Reduction of costs by losses due to the automation of the processes.

- Increase the control of the plant and its processes to increase the degree of reliability in the preparation of different foods.

- Traceability

- Monitoring and reliability in the processes carried out until reaching the final product. Specific information on the type of product, applied temperatures, sequence in the processes, quantity and dosage of the different components within the production chain.

TECHNOLOGY: RADIO FREQUENCY IDENTIFICATION (RFID)

Inventory management

- With RFID technology we can track a product from the supplier up to one estate or livestock, pig or poultry development. With RFID tags you can indicate quantity of product in stock. The message is then sent to inventory management software, which can efficiently check product levels at any time without having to manually count.

- Customer experience

- Thanks to the RFID tags In the management of Inventory and the traceability finished product, buyers have more information available than ever about the food they receive and how were they made , ingredients, quantities, along with the assurance of knowing where the products come from and how they were handled.

RFID food safety

- The RFID systems can be used to ensure that food products sensitive remain within a safe temperature range and conditions during the transport , the storage and the RFID tags can function as a temperature data logger and as a supply chain tracking tool. Tag combination RFID and of record temperature control provides processors with a means to meet Hazard Analysis Critical Control Point (HACCP) requirements.

- RFID also can Track goods along the production chain.

- Reception of raw materials

- The use of the RFID technology in receiving goods allows you to reduce working hours by do not must disassemble physically heavy and large pallets. You also get the highest data collection reliability with automatic entry into your code.

- Increase your control and efficiency

- The technology RFID / NFC effectively control and label your products. Maintenance is carried out intelligently, precisely, safely and without wasting time. Less manpower and possibility of diminish in large percentage human error. It is a reliable and safe technology.

- Profits compared to conventional labeling:

- Capture: do not code of bars. Not needed Contact visual to scan, no more tag searching. The system detects each element by radio frequency.

- Back: all the information is safe in the system without data loss.

- Reading: dust or dirt are not impediments to perform the reading.

- Durability: resistant at high / low temperatures, reliable over time.

- Integration: it can be integrated completely invisibly and safely into products and objects.

- Online RFID processes

- With the use of RFID tags and antennas located strategically , the information generated in each process will be obtained and stored automatically and the alerts in real time will keep it updated according to your configuration requirements.

Traceability

Monitoring and reliability in the processes carried out until reaching the final product. Specific information on the type of product, applied temperatures, sequence in the processes, quantity and dosage of the different components within the production chain.

Inventory management

With RFID technology we can track a product from the supplier to a farm or livestock, pig or poultry development, with RFID tags it can indicate quantity of product in stock. The message is then sent to your inventory management software, which can efficiently check product levels at any time without having to manually count.

Customer experience

Thanks to RFID tags in inventory management and traceability of the finished product, buyers have more information available than ever about the food they receive and how it was made, ingredients, quantities, along with the security of knowing where the products come from. and how they were manipulated.

RFID food safety

RFID systems can be used to ensure that sensitive food products remain within a safe temperature range and conditions during transportation, storage, and processing. RFID tags can function as a temperature data logger and as a supply chain tracking tool. The combination of RFID and temperature recording tags provides processors with a means to meet Hazard Analysis and Critical Control Point (HACCP) requirements. RFID can also track goods throughout the production chain.

Reception of raw materials

The use of RFID technology in the reception of goods allows you to reduce working hours by not having to physically disassemble heavy and large pallets. You also get the highest data collection reliability with automatic entry into your code.

Increase your control and efficiency

RFID / NFC technology effectively controls and labels your products. Maintenance is carried out intelligently, precisely, safely and without wasting time. Less manpower and possibility of human error. It is a reliable and safe technology.

Benefits compared to conventional labeling:

Capture: no barcode. No eye contact needed to scan, no more searching for labels. The system detects each element by radio frequency.

Back: all information is secure in the system without data loss.

Reading: dust or dirt are not impediments to reading.

Durability: resistant to high / low temperatures, reliable over time.

Integration: it can be integrated completely invisibly and safely into products and objects.

Online RFID processes

With the use of RFID tags and strategically located antennas, the information generated in each process will be obtained and stored automatically and the alerts in real time will keep you updated according to the requirements of your configuration.

Protect your products RFID / NFC transponders have worldwide unique serial numbers called UIDs. Safety-relevant information can be stored on your chips and RFID / NFC transponders can be almost invisibly integrated into products and objects. This makes them a much smarter way to secure and identify objects than stamps, magnetic stripes, and fingerprints.

Benefits compared to other methods:

Originality: serial number unique globally that cannot be copied.

Reading distance: scanning no contact : can be reduced to a very short distance if necessary.

Flexibility: content of data dynamically modifiable instead of static information.

Integration: it can be integrated completely invisibly and safely into products.

Self destruction: chip functions are destroyed if tampering is attempted.

Multiple raw materials warehouse.