Description

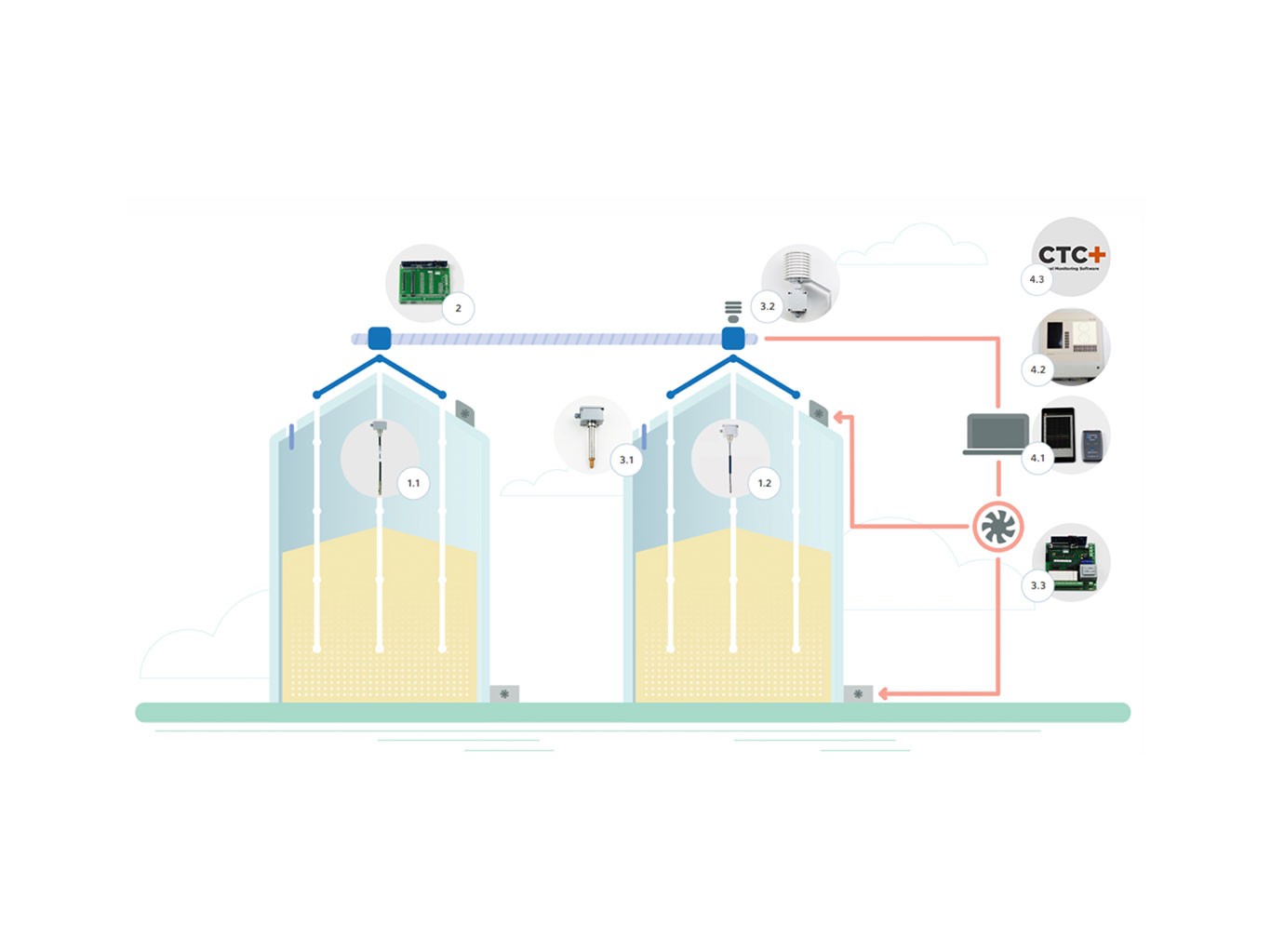

Grain moisture and temperature measurement

Start and stop of the main fans through the Set point established in the system.

Anti-condensation probes .

Temperature and humidity probes

|

|

|

TEMPERATURE PROBE

Made of smooth, flexible and small diameter tube that reduces the traction exerted on the silo roof. The cable-sensor measure , through calibrated sensors , the temperature to different levels . The ease of removal and re-insertion of the sensor cable (even with a full silo) facilitates any repair, verification and calibration. Unlimited sensors and separated by the distance that the client wishes

TEMPERATURE AND HUMIDITY PROBE

Smooth and flexible tube with calibrated sensors that measure the temperature and humidity of the stored grain. Unlimited sensors and separated by the distance that the client wishes.

ANTI-CONDENSATION PROBE

![]()

It measures the relative humidity and air temperature between the cereal and the roof of the silo. It controls the starting and stopping of the roof extractors, preventing condensation from forming both on the walls and on the roof of the silo.

RELAY MODULE

With voltage-free contacts where the fans will be connected for an automatic start and / or stop according to the selected parameters. It can also be used as an alarm signal to import into your PLC / SCADA systems.

MANUAL CONTROL CENTER

System designed for small facilities and medium where a PC cannot be used. It consists of a synoptic, an LCD screen and a numeric keyboard to select probe and silo. Optionally it can go with printer.

CTC PLUS SOFTWARE

Developed for those seeking the maximum quality of their cereals. It allows control from several PCs, export and import information and an overview of the entire plant with the current temperature relationship and its history.

CHARACTERISTICS

PREVIEW WINDOW

- Facility floor plan

- Plant layout of the probes of the selected silo

- Information on silos, probes and sensors

- Thermography: thermographic vision of the temperatures at the selected altitude

- Information on the current filling status of the silo

GRAPHICS WINDOW

The information history of all the sensors installed in the storage plant is stored in a database that generates graphs for better control of your grain.

The graphics allow visualize, for each silo and at different heights within it, the following parameters over a period of time:

- Temperature: allows the display of heating trends or cooling processes.

- Humidity: shows the humidity Equilibrium (EMC) helping the user to prevent fermentation outbreaks.

- Stock control: shows the amount of cereal stored by displaying the filling and / or emptying cycles.

- Ventilation: allows you to control the number of hours that the ventilation has been working.

CONNECTIVITY

All the information on the CTC + can be consulted via:

- Internet: from anywhere and mobile device

- SCADA / PLC: via OPC or Modbus protocols

VENTILATION

- ON: forces the fans to start

- OFF: force the fans to stop

- CAR: ventilation will work if all conditions are met:

- Maximum storage temperature: If any sensor in the silo exceeds this value, it will be a ventilation condition.

- Minimum temperature differential: safety value that allows ventilation only when the ambient temperature is the value indicated below the temperature of the grain.

- Minimum / Maximum Humidity (%): the relative humidity outside is between these values.

- Time interval 1 and 2: time slots that allow ventilation.

PSYCHROMETRIC: of the conditions of temperature and humidity equilibrium (EMC) of the stored grain and the ambient temperature and relative humidity, the system will ventilate according to the psychrometric graphs to preserve the grain in the desired conditions:

- Maximum storage temperature: maximum temperature value at which we want to preserve the grain.

- Hysteresis: differential on and off of the fan. The predictive system warns the user if he wants to ventilate since there is a tendency for the grain to approach a risk zone.

- Time interval 1 and 2: time slots that allow ventilation.

ROOF REMOVAL

Thanks to the probe anti-condensation that provides the temperature and relative humidity of the air inside the silo, the system determines whether or not condensation will occur on the silo walls. If there is a danger of condensation, the extractors will start.

- Start / stop temperature difference: safety value that allows the start or stop of the extractors only when the ambient temperature is below these values.