Description

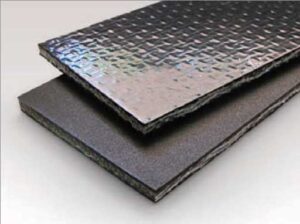

GRAINS – RUBBER AND PVC BELTS

Premium rubber grain belt with the highest oil resistance and low elasticity, designed for the grain industry where oleaginous and controlled mineral or vegetable oil sprays contact the belt.

Superior oil resistance, static conductivity according to the OSHA ISO 284 , and for the MSHA 2G The fire resistant rubber belt is ideal for handling ground grains, rice, fertilizers, feed and oil treated grains.

PVC , BLACK AND WHITE – MSHA 2G / OSHA 284 – The general cargo belt is constructed of interlocking material with plastic covers. PVC black on both sides, with quality options FDA as well as PVGE . It is ideal for handling whole grains, rice, fertilizers, refined sugar, and balanced foods.

BELTS FOR INDUSTRIAL USE AND GRADE 2 EPDM

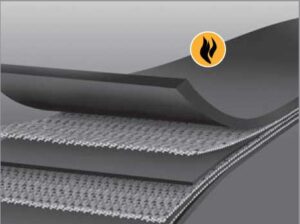

SOLAR SHIELD XL 750

FEATURES AND BENEFITS

ABRASIVE RESISTANT BELTS – INDUSTRIAL APPLICATIONS – SBR – Grade 2

Rubber belts for standard load, ideal for heavier industrial uses such as conglomerate, cement, fly ash, minerals, salt and raw sugar.

HIGH TEMPERATURE EPDM 400 HT & 700 HT – Premium quality rubber band for high temperature. It is ideal for handling silica,

conglomerate, fly ash, cement, and other bulk materials in drying facilities. Solar Shield 400 Y XL 750 will be available in 2020.

high temperatures.

High heat resistance coating resists breaking and hardening.

SOLAR SHIELD XL 750 has durability while retaining

flexibility despite heavy loads and conditions. Fewer cracks and hardening mean longer life and lower replacement costs. SOLAR SHIELD XL 750 compound improves resistance to high temperatures beyond our 400 F (204 C) compound and extends the life of the belt.

SOLAR SHIELD XL 750 was designed to handle loads of hot materials intermittently up to 750 F (399 C) providing long life in severe heat.

Resistance to high temperatures, breakage, abrasion and elongation, load back load.

SOLAR SHIELD XL 750 endure long exposure.

Reduced maintenance and less “downtime” help lower operating costs.